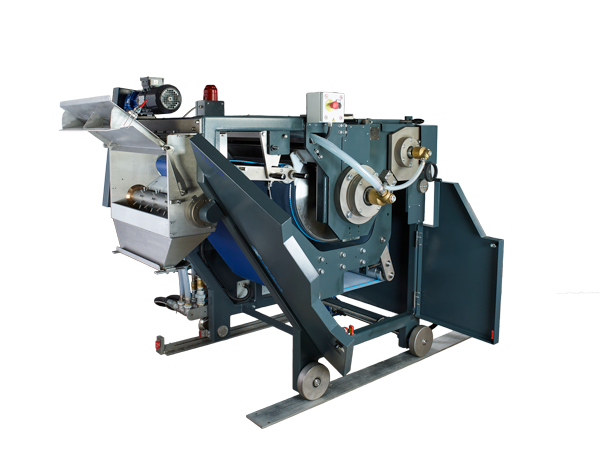

Xtrutech are happy to announce the release of the XTDC3, the latest generation of Xtrutech’s compact Drum Coolers. The XTDC3 features some innovative upgrades to make cleaning and maintenance even simpler. Our new Drum Cooler made its initial premiere at the European Coatings Show, where you may have seen our Service Engineers demonstrating some of these capabilities on the stand.

For example, the blue polyurethane belt (pictured) can easily be removed using the side access panel which decreases the time spent on cleaning duties. As a result, belt replacements are both quick and straightforward. The belt is used to hold product against our stainless-steel cooling roll and acts to transport the chilled sheet to the kibbler unit.

The Kibbler unit is complete with a spiralised mini breaker to reduce the chilled extrudate sheet into grindable chips and to further reduce cleaning times we offer the optional extra of a “removable kibbler shaft”. This allows the shaft to be taken out of the machine, cleaned, and then efficiently replaced.

The XTDC3 can also be paired with Xtrutech’s XTS35 Twin Screw Extruder, for a seamlessly integrated complete extruder line. We have included a Siemens Remote PLC to reduce the wiring between the two machines and as an extra safety precaution, the XTDC3 also includes a fully integrated safety system to prevent the rolls from turning whilst out of position. Additionally, when paired with an XTS Extruder the Drum Cooler can support operational control from the Extruder’s HMI.

Want to learn more about the XTDC Drum Coolers? Contact our sales team today via sales@xtrutech.com or by calling +44 (0)1782 621 122.